S-Maxx™ Wireline Drill Rod

Today’s drilling environment involves challenges previous generations rarely faced, if ever. From deeper, harder-to-access deposits to operational challenges with automated rod handlers to tighter margins from a more competitive and volatile global mineral exploration market, today’s driller needs efficient solutions to difficult situations.

Drilling has changed – have your drill rods changed to meet these challenges?

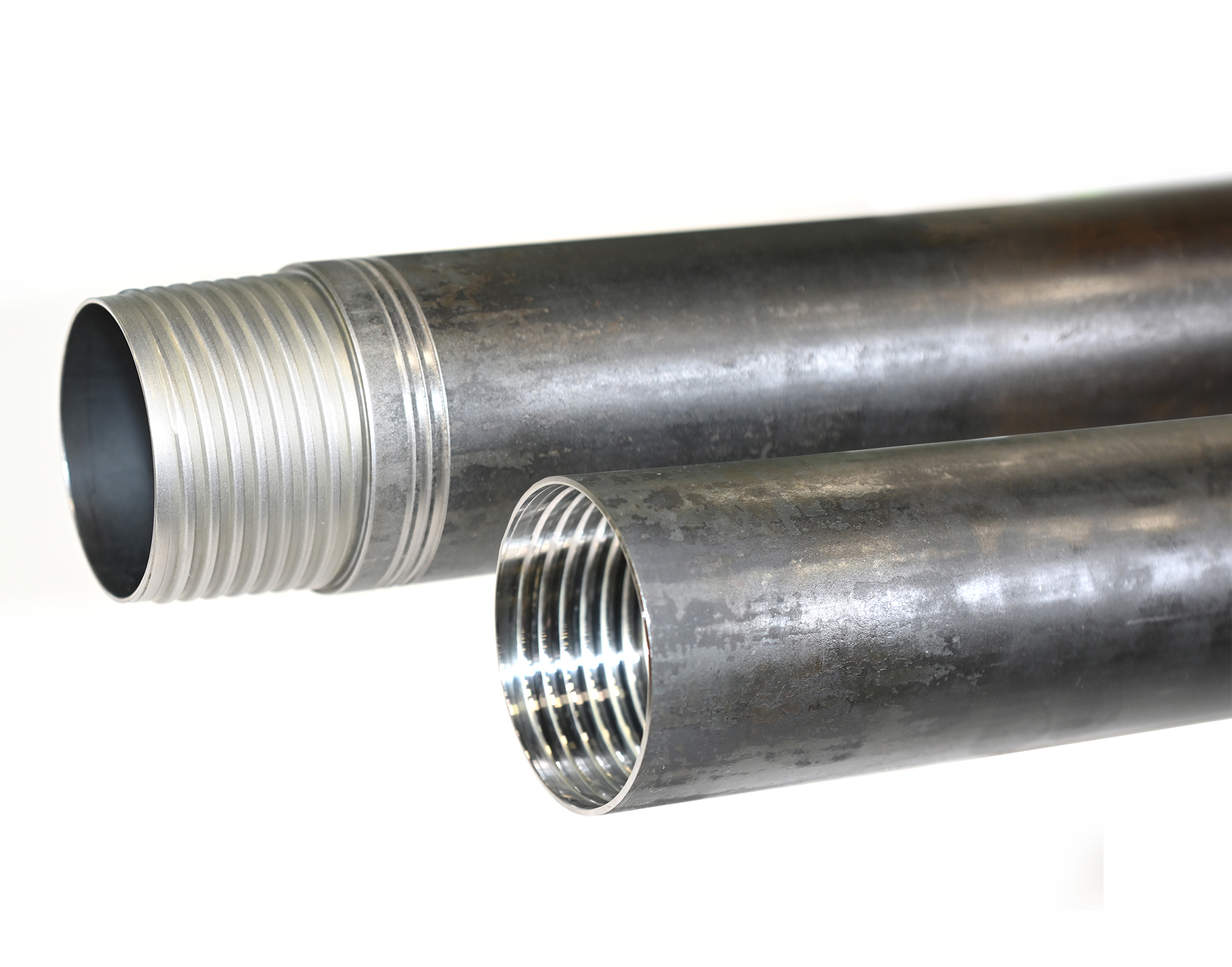

Introducing the next generation wireline drill rods: S-Maxx by Di-Corp. Specifically designed to meet the needs of today’s modern driller, S-Maxx drill rods’ unique dual start thread helps drillers reach greater depths and achieve new limits. With S-Maxx, you gain efficiency by preventing cross-threading – resulting in faster make and breaks. You gain efficiency from more durable rods, resulting in cleaner shifts, reduced downtime, and increased productivity. By investing slightly more in drilling rods, you gain lower cost per meter drilled throughout the project.

Di-Corp spent years designing, researching, developing, improving, and testing the S-Maxx to ensure it was ready to meet the needs of modern drilling and match our high standards for drill rod quality and durability. In doing so, we paired our demonstrated commitment to quality rods found in all Drillers Edge wireline rods with a revolutionary new thread form uniquely capable of delivering unmatched drilling performance.

Max rod life. Max joint strength. Max depth capacity. Max efficiency.

Download the S-Maxx Drill Rod brochure

[English] [Français] [Español]

The S-Maxx name comes from two parts: our patented S-shaped interlocked profile thread and the maximum performance delivered by the rod. The dual start S thread delivers more surface area and contact than previous thread forms, resulting in faster make and breaks and the highest torsional and tensile strength in the market.

The S-shaped curvature of the load flank creates a self-locking thread profile resistant to bulging while the large corner radii improve fatigue cycling by eliminating areas of high stress concentration, improving the cycle life of the joint.

The dual start thread allows for a finer thread pitch allowing for more threads to be engaged without sacrificing make up speed. This provides a more even load distribution along the length of the thread, improving performance when compared to traditional designs. Additionally, the thread form prevents cross-threading and jamming to ensure quick and easy make up and allows the driller to remain out of harm’s way.

The new S thread is machined onto Drillers Edge tubing, undergoing the same manufacturing processes that have given our rods a global reputation for durability. Drillers Edge rods have routinely proven to last two times longer than industry standard.

- Superior joint strength resulting in the highest torsional and tensile strength on the market.

- Reach greater depths – depth capacity of 4300 meters.

- Prevent cross-threading with dual start threading for faster make and breaks.

- Ideal for automated rod handling.

- Up to two times normal drill string life.

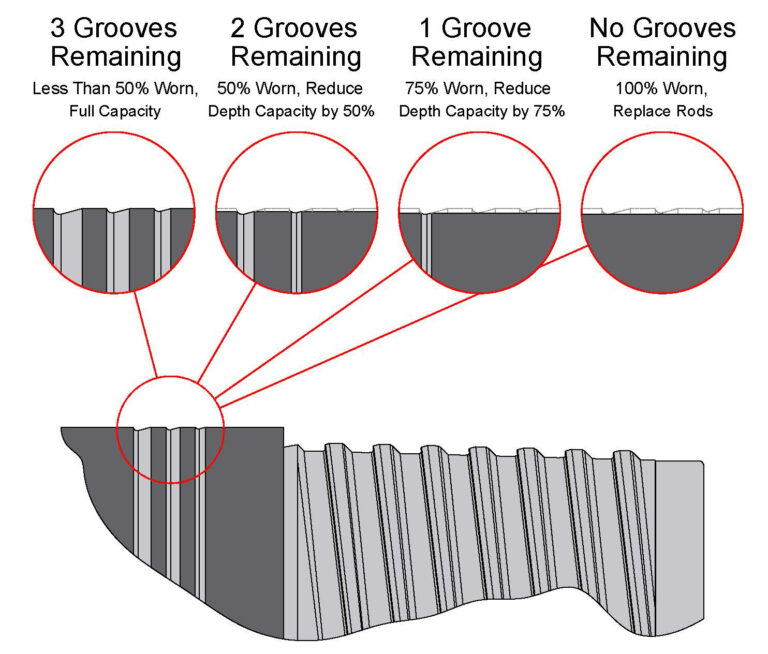

- Identification grooves provide quick visual reference on overall wear on rods.

HIGH-QUALITY MATERIALS

- Steel is specified to the highest industry standards.

- Processed with an additional stress relief heat treatment to eliminate bent rods.

- Finished with a specialty hardening process that is continuously monitored and adjusted to each batch of material to ensure consistency.

PRECISION MACHINED THREADS

- Pin threads are precision machined in our state-of-the-art manufacturing facility by industry-experienced professionals.

- Unparalleled quality control in-house ensures consistent quality of finished product

WARNING: All threads are precision machined. Mixing Di-Corp rods with other manufacturers’ rods, adaptors, or threaded accessories is not recommended. Failure to adhere to this recommendation may cause premature failure; an inspection may result in the warranty becoming void.

The S-Maxx™ is engineered to allow drillers to reach the max depth with max durability. However, as the outer diameter (OD) of the rod wears down, depth capacity should be derated to compensate for the thinning of the box wall thickness.

S-Maxx makes it easy to know how much wear a rod has experienced and thus how much to reduce depth capacity with our unique identification grooves. The identification grooves are designed with three grooves of different known diameters. This is to provide the drillers with a quick and easy reference to

the percentage of OD wear currently present on the body of the rod without the use of any specialty tools or devices.

As the grooves begin to wear off from the body of the rods, the depth capacity should be derated by the same percentage indicated in the diagram below. This

will help ensure that rod wear is properly monitored and that worn rods are retired to shallower/easier holes or scrapped out accordingly.

Once the identification grooves are completely worn off, the rods can be scrapped out with the confidence that they were not disposed of prematurely and that you are getting max value from them.

| Part Number | Description |

|---|---|

| 106277 | DRILL ROD, BS 3m |

| 106279 | DRILL ROD, BS 1.5m |

| 106276 | DRILL ROD, BS 10ft |

| 106278 | DRILL ROD, BS 5ft |

| 105878 | DRILL ROD, NS 3m |

| 105879 | DRILL ROD, NS 1.5m |

| 105880 | DRILL ROD, NS 10ft |

| 105881 | DRILL ROD, NS 5ft |

| 106040 | DRILL ROD, NS 3m LITE |

| 106041 | DRILL ROD, NS 10ft LITE |

| 106201 | DRILL ROD, HS 3m |

| 106203 | DRILL ROD, HS 1.5m |

| 106200 | DRILL ROD, HS 10ft |

| 106202 | DRILL ROD, HS 5ft |

| 106205 | DRILL ROD, HS 3m LITE |

| 106204 | DRILL ROD, HS 10ft LITE |

View our brochure for full specifications.

- All rods are packaged and sold in bundles

- The entire length of the rod is coated with Krown rust protection oil

- Box and pin ends are protected with plastic end caps to ensure the anti-galling thread compound does not get contaminated or removed before the first use

- Hexagonal bundle end caps further protect the rod ends during shipping and make them easier to stack